Bifurcated fan Dubai

- Home

- Bifurcated fan Dubai

Bifurcated Fan Dubai

Dynamic Ventilation, the leading manufacturer of bifurcated fans in Dubai. If you need to set Bifurcated Fan in Dubai, we provides you the best for your industry. What sets Bifurcated Fan apart is their distinctive motor placement outside the primary airflow stream.

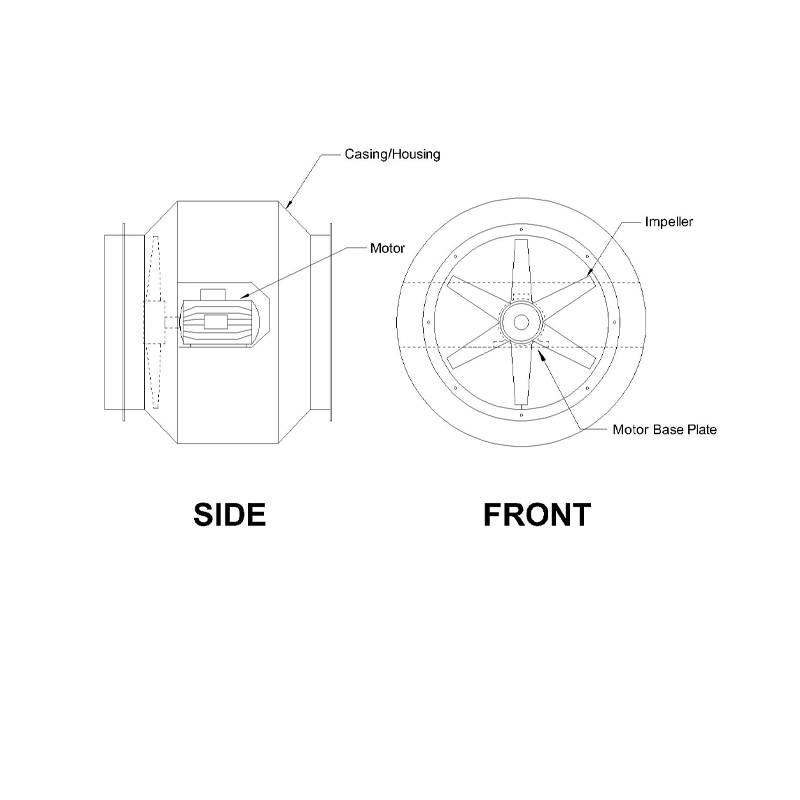

What Is a Bifurcated Fan?

A Bifurcated Fan is a specialized industrial fan designed to handle high-temperature applications with finesse. What sets them apart is their distinctive motor placement outside the primary airflow stream. This design ensures that the fan’s motor remains protected from extreme temperatures and potentially corrosive or abrasive materials present in the air. A Bifurcated Fan is a specialized industrial fan designed to handle high-temperature applications with finesse. What sets them apart is their distinctive motor placement outside the primary airflow stream. This design ensures that the fan’s motor remains protected from extreme temperatures and potentially corrosive or abrasive materials present in the air.

Dynamic Ventilation, a trusted manufacturer and dealer of Bifurcated Fans in Dubai, offers precise airflow and temperature control, making them invaluable for industries that demand consistent and controlled conditions. Their contributions extend beyond cooling; they play a pivotal role in enhancing the efficiency and safety of a diverse range of industrial processes, establishing them as indispensable assets in critical settings.

Structural Features of Bifurcated Fan

Motor Placement

The defining structural feature of Bifurcated Fans is the strategic placement of the motor. It is kept outside the main airflow stream, reducing the risk of motor exposure to high temperatures.

Durable Construction

These fans are constructed with durability in mind. They are built to withstand the harsh conditions of industrial settings and high-temperature environments, ensuring longevity and reliable performance.

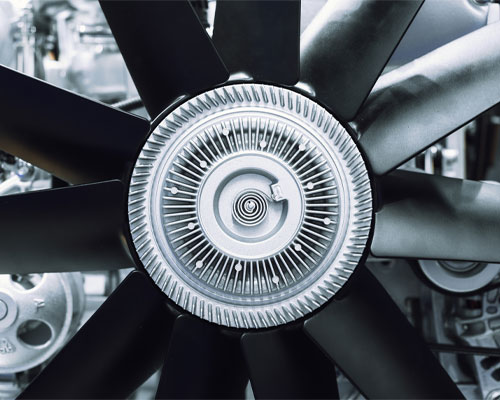

Functional Features of Bifurcated Fan

High-Temperature Resistance

Bifurcated Fans dubai are engineered to endure and thrive in high-temperature environments. They are designed to provide effective cooling and ventilation without succumbing to the heat.

Precise Airflow Control

These fans excel in maintaining precise airflow and temperature control, making them ideal for applications where temperature consistency is paramount.

Uses of Bifurcated Fan

Bifurcated Fans find extensive use in various industries due to their unique ability to operate effectively in high-temperature environments while providing precise airflow control. It includes industrial furnaces, kilns, dying process, heat treating etc.

Industrial Furnaces

In industrial furnaces, where temperatures soar to extreme levels, Bifurcated Fans Dubai ensure efficient airflow and temperature control, safeguarding both equipment and processes.

Here’s a more detailed explanation of their uses in different industrial sectors

Metallurgy and Metal Processing

Ceramics and Pottery Production

Food Processing

Chemical and Petrochemical

Glass Manufacturing

Automotive and Aerospace

Textile Industry

Wood and Paper Processing

Environmental Control

Energy Generation

Building Materials

Oil and Gas

Maintenance and Caring

To ensure the longevity and reliability of Bifurcated Fans in Dubai, regular maintenance is essential:

Inspect Regularly

Clean Blades and Motor

Lubricate Moving Parts

Why Choose Dynamic Ventilation for Bifurcated Fans?

Bifurcated fans, with their unique motor placement and high-temperature capabilities, are indispensable tools in industries where extreme heat is a constant factor. Dynamic Ventilation, the leading manufacturer of bifurcated fans in Dubai, plays a pivotal role in ensuring both safety and efficiency.

Engineering Expertise

Dynamic Ventilation possesses extensive expertise in fan engineering, ensuring that their Bifurcated Fans in dubai are designed for precision and performance in high-temperature environments.

Custom Solutions

They offer customizable Bifurcated Fans, allowing you to tailor the fan to your specific needs, whether it's size, airflow capacity, or other features.

Quality Assurance

Dynamic Ventilation's commitment to quality ensures that their fans are built to withstand the rigors of industrial settings and provide reliable, long-lasting performance.

Safety and Compliance

Their fans adhere to stringent safety standards and are suitable for use in diverse industrial applications, guaranteeing both safety and compliance.

Frequently Asked Questions

What are Bifurcated Fans, and how do they differ from regular industrial fans?

Bifurcated Fans are specialized industrial fans designed to operate effectively in high-temperature environments. What sets them apart is their unique motor placement outside the main airflow stream. This design protects the motor from extreme heat and potential exposure to contaminants, making them ideal for applications where regular industrial fans may not withstand the heat.

What are the typical applications for Bifurcated Fans in industrial settings?

Bifurcated Fans find extensive use in various industries. Some typical applications include metallurgy for heat treatment, ceramics and pottery kilns, food processing for drying, chemical and petrochemical processes, glass manufacturing, automotive and aerospace heat treatment, textile drying, wood and paper processing, environmental control systems, power generation, building materials production, and oil and gas refining processes. These fans excel in maintaining precise temperature control in high-temperature environments.

Can Bifurcated Fans be customized to meet specific industrial requirements?

Yes, many manufacturers, including Dynamic Ventilation, offer customization options for Bifurcated Fans. These customizations can include variations in fan size, airflow capacity, motor specifications, and other features to align with specific industrial needs. Customized Bifurcated Fans are tailored to meet the precise requirements of various applications.

What maintenance practices are necessary to ensure the longevity and performance of Bifurcated Fans?

Proper maintenance is crucial to extend the lifespan and reliability of Bifurcated Fans. Regularly inspect the fan for signs of wear or damage, especially focusing on the motor, blades, and safety features. Clean the blades and motor as needed to remove dust and debris that may accumulate. Additionally, lubricate moving parts as recommended by the manufacturer to prevent friction and ensure smooth operation. Following these maintenance practices will help maintain the fan's optimal performance in high-temperature environments.